■ Structure of Pump

Arimitsu Industry Co., Ltd manufactures a line of high quality pumps designed to fit wide range of applications. Our pumps are offered in varying sizes from less 1kw to over 330kw.We briefly introduce the structure of a general plunger-type pump under stable performance here.

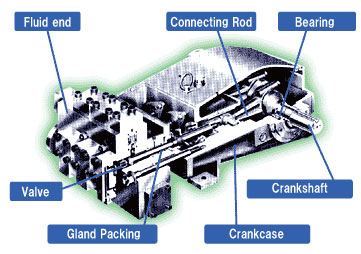

■ Pump Structure

- Fluid end

Cylinder, Discharge Manifold, and Suction Manifold are strong, chemical and corrosion resistant. These parts are available in forged brass, forged steel or machined precipitated hardening stainless steel and depending on the customer's applications. - Valve

Our valves use alumina ceramic seat discs welded with high-strength metal to provide corrosion and chemical resistance. This provides long operational life with a wide range of liquid compounds.

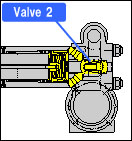

- Valve2

For large class pumps we use an in-line valve design with a smaller fluid end for weight reduction and ease of maintenance.

For large class pumps we use an in-line valve design with a smaller fluid end for weight reduction and ease of maintenance.

- Valve2

- Gland Packing

We use leak resistant, self lubricating and cooling gland packings which are designed to protect against liquid leakage when pressurized. We also have aramid packings available for specific high performance needs. - Crankcase

We use aluminum die cast crankcase which provides weight reduction for small and medium class pumps. For large class pumps we use aluminum die cast and ductile iron to provide added strength. - Connecting Rod

We use aluminum die cast and forged connecting rods for weight reduction for our small and medium class pumps. For our large class pumps, we use white metal forged ductile for superior strength, smooth movement and durability. - Bearing

We use high quality bearings for long operational life to withstand consecutive driving and repetitive ON-OFF conditions. - Crankshaft

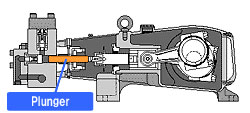

We use superior ductile cast iron and chrome molybdenum for strengthened surface treatment. This provides long life under severe operation conditions. - Plunger

To provide durability and corrosion resistance, we use plungers made of silicon carbide and alumina ceramic. In addition, our large class pumps have an automatic adjusting system for the central axis and connecting rod. Our pumps are carefully designed for ease of dismantling and maintenance.

To provide durability and corrosion resistance, we use plungers made of silicon carbide and alumina ceramic. In addition, our large class pumps have an automatic adjusting system for the central axis and connecting rod. Our pumps are carefully designed for ease of dismantling and maintenance.