■ What is the most favorable greenhouse sprayer ?

- Being an unmanned pest control machine.

[Advantage]- workers can make the pest control without smoking the chemicals directly and suffering from the pesticide exposure.

- Mist particle being ultrafine particles.

Size of particles・・・Diameter of falling particle is about 2-5 μ

[Advantage]- Unmanned dispersion is possible・・・Pesticide can disperse to the wide areas from one place.

- Sterilization of the space in greenhouse・・・Sterilizing all inside of greenhouse (crops, a pillar, plastic cover, air etc).

- The crops are not polluted with a pesticide.

- Being a little water to spray(Low volume spraying)(Low Volume Spraying).

[Advantage]- Control-effect for over-humidity.The humidity in the greenhouse does not rise even after the sterilization.

- Resource saving、 Labor saving

Name of the dispersion method Quantity of dispersion (per 10 g) HV(High volume) method Habitual spraying Over 50L LV(Low volume) method Low Volume Spraying 600mL~50L ULV(Ultra low volume) method Ultra low volume spraying Under 600mL ※In case of Low Volume Spraying in greenhouse:3L~7L/10a

In case of power sprayer

Over 200L/10a

In case of greenhouse spraying

5L/10a - The compatibility with the pesticide being good.

- Various registered pesticides be usable.

- There not being the resolution of the pesticide by the heat (normal temperature mist).

※The organic pesticide and the antibiotic pesticide are vulnerable to heat. - Using the materials of sprayers which do not corrode with a pesticide.

■ How to make the ultrafine particles for greenhouse sprayer

In case of greenhouse sprayer, air injection atomization method by using compressed air is adopted and it produces the ultrafine particles by Arimitsu Air atomizing nozzle (special 2 fluid and normal temperature spraying nozzle) which is special structure of the original development.

■ The principle and structure of ultrafine particles production

It is in structure to produce the particles smaller (it is less than 12μm near the spray nozzle orifice and diameter of falling particles are 2-5μm ) by inflating compressed air at speed of sound into a whirlpool in order to produce ultrafine particles.

■ Characteristic by dispersion of ultrafine particles

The particles have ball shape, but thinks with a cube to explain it clearly.

|

Cube 1mm on each side Capacity 1mm3 Covering area 1mm2 |

Divide the length, the side, the height of this cube in ten each

Divide it into a cube of one side of 0.1mm and display it.

|

Capacity 1mm3 Covering area 10mm2 |

Therefore, it covers the large area by dividing even the same capacity. Conversely it is enabled at less capacity if it is divided it in small to cover the same area.

It is the same thing even if this is replaced with a ball.

Therefore, the coating areas increase by making particles smaller and it can adhere particles uniformly. and it may spray a pesticide on the crops without blind spots.

|

|

| Adhesion particles of power sprayer (150~300Micrometer) |

Adhesion particles of house sprayer (2.5~3Micrometer) |

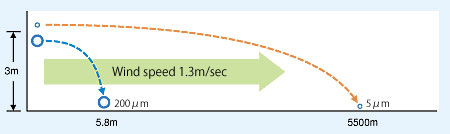

Relations between particle size and the fall of the drop of water (particle)

| Particle size (Micrometer) |

Time until falling down from 3m height to the ground |

Fall velocity (m/sec) |

1.3m/sec, distance to be scattered before falling down from 3m height to the ground |

|---|---|---|---|

| 5 | 67min.30sec | - | 5,500m |

| 33 | 1min.33sec | 0.034 | 125m |

| 100 | 11sec | 0.28 | 15m |

| 200 | 4sec | 0.73 | 5.8m |

| 500 | 2sec | 2.0 | 2.1m |

| 1,000 | 1sec | 1.8 | 1.5m |

1micrometer(1μm)=1/1000mm

|

|||

■ Good points of the Arimitsu greenhouse sprayer

- Low volume spraying method.

- Normal temperature fogger method.

- Unmanned dispersion. Saving the labor and safe pest control.

- Economical and simple operation.

- Quality improves. The dirt on the crops decreases.